Place:

Fossil Fuel Electric Generation Plant

Challenge:

A 2” Chemical condensate return line operating at 125psi and 212f had developed an erosion leak at and elbow. The system supplied chemicals to emission control systems that could not be turned off without shutting down the 700-megawatt generator.

Solution:

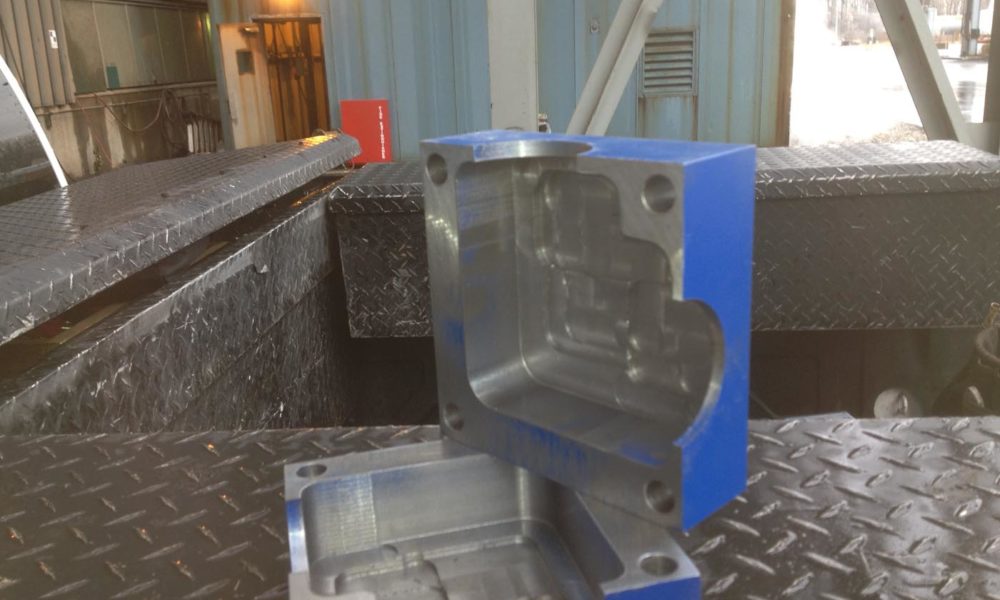

RJ Stacey designed and manufactured a custom repair enclosure specifically for the pressure, temperature, and chemical requirements of this application. Within 16hrs of the initial call, the repair was complete. Because the enclosure was needed so quickly, we opted to eliminate channels in the termination ends that typically hold a packing gland. Instead, we opted to install the enclosure with a simpler metal on metal seal and injected the enclosure with an appropriately chemical resistant sealant.

Results/Benefits:

The resulting repair was 100% bubble tight and lasted over 7 months until the next scheduled periodic outage when the entire run of pipe was replaced. The plant experiences no disruption of operations during this repair.