Place:

Power Generation Station

Challenge:

Plant Operations requested the installation of fourteen (14) Pro-Sense Data Probes into an existing 36” Steam main operating at 400psi and 450f. The job needed to be done immediately in order to provide data that would allow for more efficient operations; however, the next outage was a year away.

Solution:

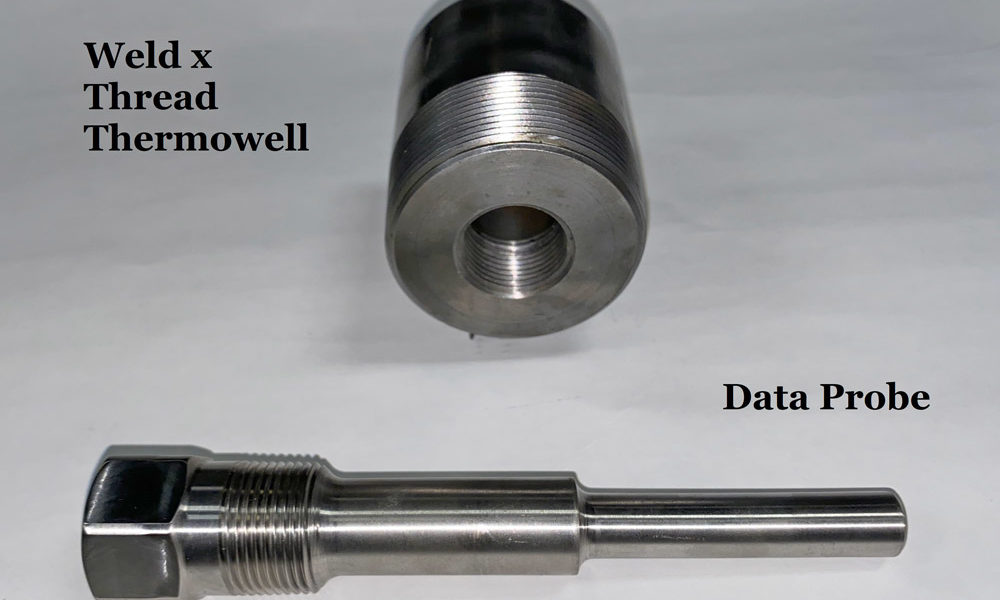

RJ Stacey met with onsite plant engineers to determine the layout of all Data Point locations. This was done to ensure space available would be compatible with RJ Stacey equipment requirements. (Due to the compact nature of our tapping and setting machines, all first-choice locations were feasible.) Next, RJ Stacey’s dual-threaded thermowell nozzles were welded onto the pipeline, the over bored valves mounted to the 2” major thread dimension, and 2×1” hot taps completed per each location. Finally, RJ Stacey Themosetter tooling allowed each Data Probe to be set into the 1” minor thread dimension of the nozzles. Once the Probes were set into the Thermowell nozzles, the residual pressure in the machine could be safely vented and the machine removed followed by the valve.

Results/Benefits:

The use of the online Thermowell/ Data Probe installation allowed for the immediate installation of important data point equipment into the steam main. This allowed for the more efficient operation of the pipeline and increased safety. The efficiencies created greatly reduced the cost to operate the pipeline. The immediate results overshadowed all job costs.