Place:

Stove #3 at a large north American blast furnace

Challenge:

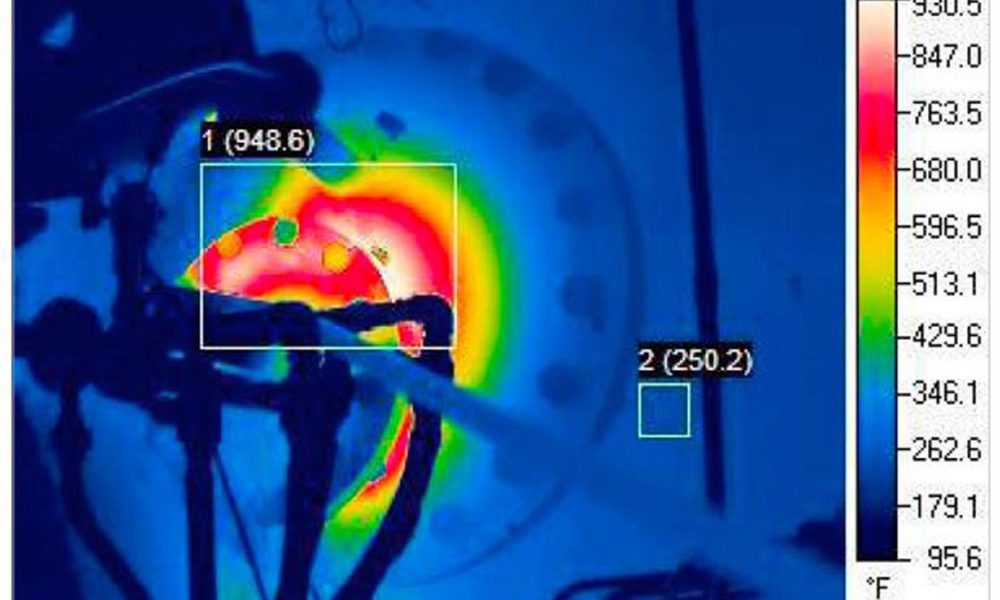

Damaged refractory had caused this stove dome inspection cover to become overheated. Plant personnel discovered the issue during operation. By the time a cooling steam lance had been put in place the Blind flange cover was glowing red in spots, the bolts had stretched significantly, and the gasket had completely blown out under pressure. Shutting down and repairing the damage conventionally was not a good option due to an adjacent stove already being out of service, this would have required a full stop of blast furnace operations.

Solution:

RJ Stacey technicians assessed the situation and immediately began working, initially only during gas cycles of the stove for safety reasons. The first step taken was to replace the bolts one at a time and get the cover back down onto the flange. Next, we peened copper stock into the flange face gap, this served two purposes: first, it acts as a replacement gasket material and immediately stops a large amount of the flow and heat. Secondly, it creates a barrier around the diameter of the flange, and this allows us to complete the final step. Using a small hot tap through the cover a pumpable sealant/refractory is injected into the cover and flange.

Results/Benefits:

The entire project was completed by RJ Stacey without any interruption of Blast furnace operations. The temperature of the cover was reduced from 850F at the beginning of the job to less than 175f at the conclusion. No welding was done of the blind to the flange, so the bottom flange and nozzle were able to be saved. This was an additional benefit to the customer when conventional repairs were made months later during a planned outage.