Place:

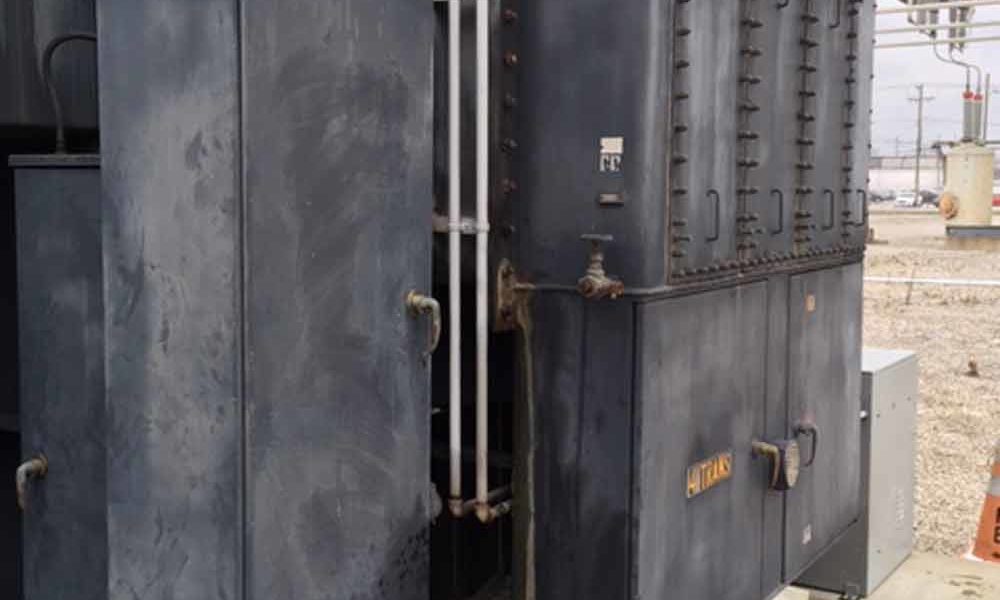

Canned Food Processing Plant

Challenge:

A plant substation transformer was found to be leaking oil at multiple locations on the lower unit. Both the major utility who owned the transformer and the corporation who owned the Canned Food Plant agreed that the leaks had to be fixed, but could not agree on a schedule to take the total plant power outage required to drain the oil and repair the transformer with conventional methods.

Solution:

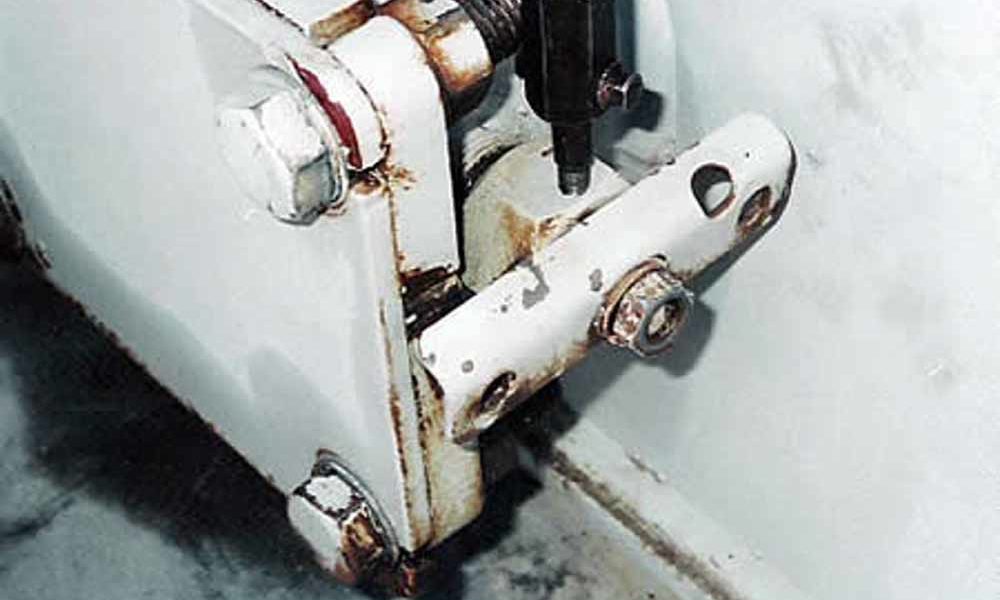

RJ Stacey inspected the transformer and determined the only leaks were at the Flapper Valve packing glands. We developed a site-specific safety plan that satisfied both corporate entities. Once the safety plan was developed, the actual job was a straightforward drill and tap packing injection. The material used was injectable RJSDielectric packing sealant. This sealant has been widely used by us on hundreds of similar electrical component applications with good results and longevity.

Results/Benefits:

All leaking valve packings were injected to a leak free state without any loss of electrical service to the plant. There was no need to drain oil. The source of the environmental concern was eliminated and a cleanup of the area was done by the power company. A year later we returned to perform the same work on additional valves in the same system.