For over 40 years, RJ Stacey has been providing pipeline services to hundreds of different companies around the globe. Our team of professional technicians will provide your company with the safest and most effective solutions for your operation's success.

A “linestop” is a means of providing an isolation point in a pipeline where none currently exists. This could be required because of inoperable valves, or branch connections without existing valves. In these situations, the ability to isolate a downstream segment of a pipe while keeping the upstream pressurized is desirable. RJ Stacey offers many types of “Linestop” depending on the requirements of pressure, temperature, flow rates, and product in the pipe. A detailed hazard assessment will be done prior to recommending a linestop method. Safety and dependability are our primary interest.

A linestop allows us to maintain, repair, and replace valves and sections of a pipeline without any service disruption. This method is often the last option before making the decision to drain or shut down a pipe system completely.

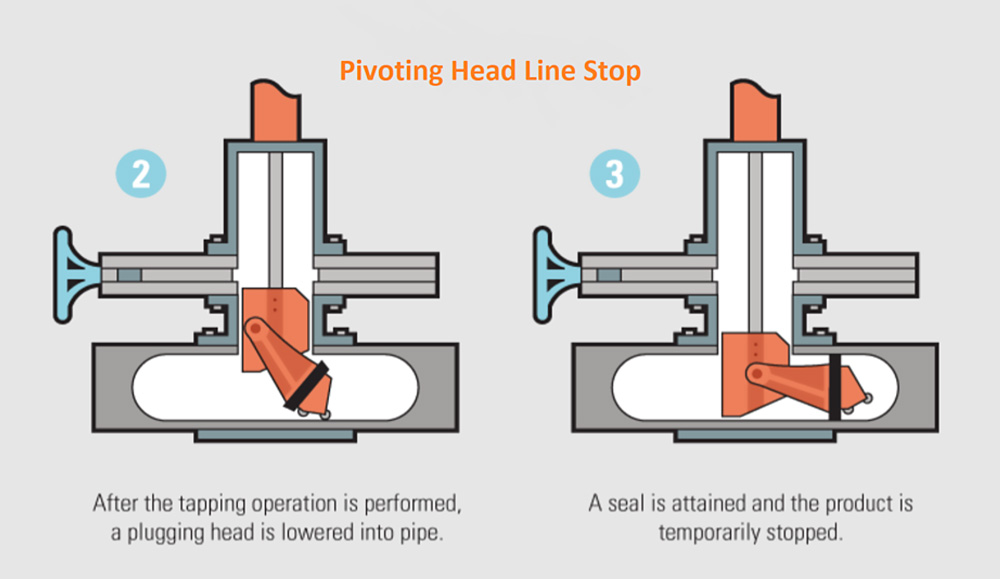

These are used for high pressure, high flow, and high-temperature line stop applications. They are also often used in applications where maximum safety margins are required. Pivot Head linestops can handle temperatures up to 700°Fand pressure up to 1,000psi. They are the most robust mechanical linestop method.

Folding head line stops are used for lower temperatures and lower pressure jobs; 200°F and 200 psi respectively. Their unique design and lighter weight allow for use in challenging settings with limited space. Another attribute of the Folding Head linestops is that it is inserted through a reduced branch hot tap. The smaller bore hot tap is desirable on many piping materials as the pipe retains greater hoop strength.

Insertable bladders offer insertion into pipelines through hot taps smaller than any other method, the advantage being the retained hoop strength of the host pipe, reduced costs for small-bore fittings and companion hot tap. Additionally, they have a large surface area interaction with the pipe id. for this reason they typically seal very well on pipes with heavy scale and surface irregularities. While typically used for fluids we also use them occasionally downstream of a Pivot Head linestop as a vapor barrier to make a “double block and bleed”.

By using proprietary polymers, we are capable of performing Pivot Head linestops on volatile organic compounds, acids, oxidizers, and extreme temperature products. We also offer bullet-style linestops where the primary seal is metal on metal with a sealant injection, this style is very useful in small bore piping of high flow and temperature combinations.

RJ Stacey utilizes both Co2 and Nitrogen freeze equipment; determining case by case which is best for a particular job. Co2 systems are lighter making it advantageous for difficult locations within a plant. While Nitrogen is valued for its fast results. Both systems bring the chosen segment of your pipeline below -200°F; freezing the liquid inside to create a safe and durable isolation plug. Highly advantageous for many reasons including extreme high-pressure tolerance, ready availability of all components, and economy due to the elimination of purchasing and installing linestop saddles.